In a box factory, if the "corrugator" machine makes the flat cardboard sheets, the Flexo Printer Slotter Die-cutter is what turns those sheets into real boxes.

This machine does many jobs at once: it prints colorful designs, cuts slots for folding, and trims the box into the right shape. In 2026, as more people shop online, having a fast and high-quality printing machine is the key to success for any box business.

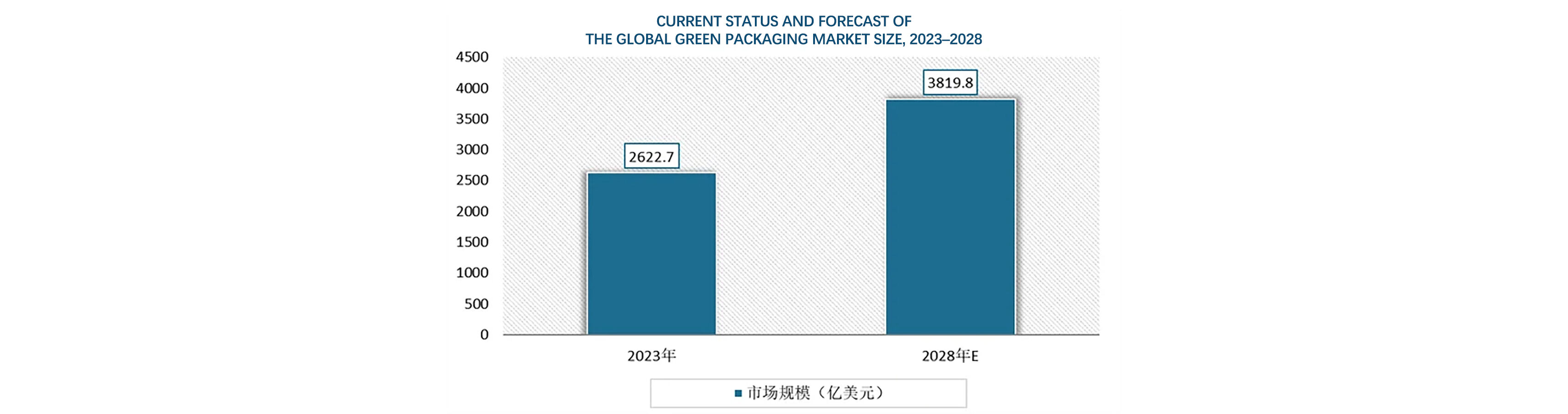

Image courtesy of chinabaogao.com

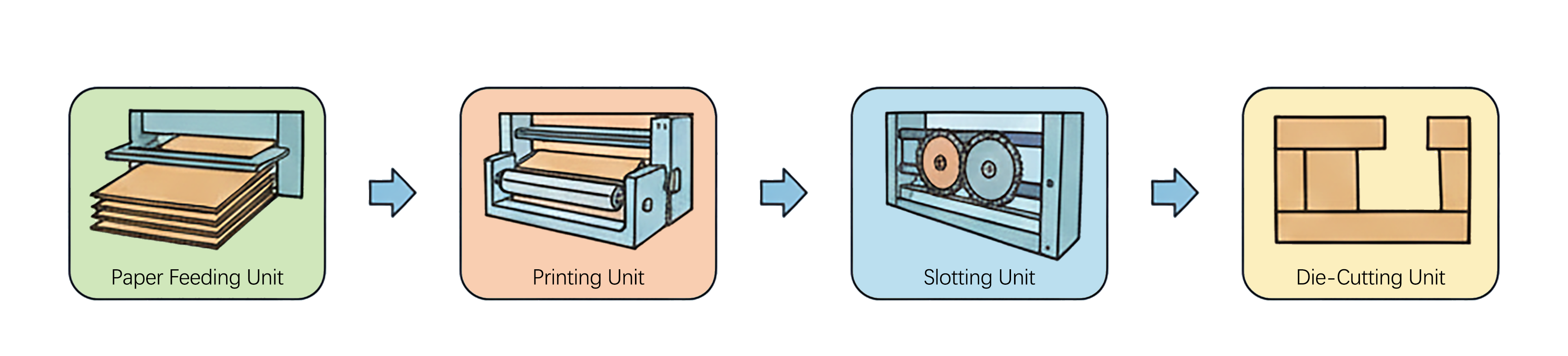

A standard machine has four sections. Each part has a special job:

● Feeding Section: This part picks up the flat cardboard and pushes it into the machine. It uses "lead edge feeding" to make sure the board moves straight without damaging the wavy layers inside.

● Printing Section: This uses "Flexo" (flexible) printing plates. It works like a giant stamp. Ink is moved from a special roller (Anilox Roller) to the plate, and then onto the cardboard. You can have 1 to 6 colors.

● Slotting Section: This part cuts the narrow gaps (slots) and presses fold lines into the board. This decides the length, width, and height of your box.

● Die-cutting Section: For special shapes like pizza boxes or mailer boxes, this part uses a sharp "die" (a wooden mold with blades) to cut out complex designs and handle holes.

Machine prices can range from tens of thousands to millions of dollars. Here is how to pick the right one:

Think about how many boxes you need to make every day:

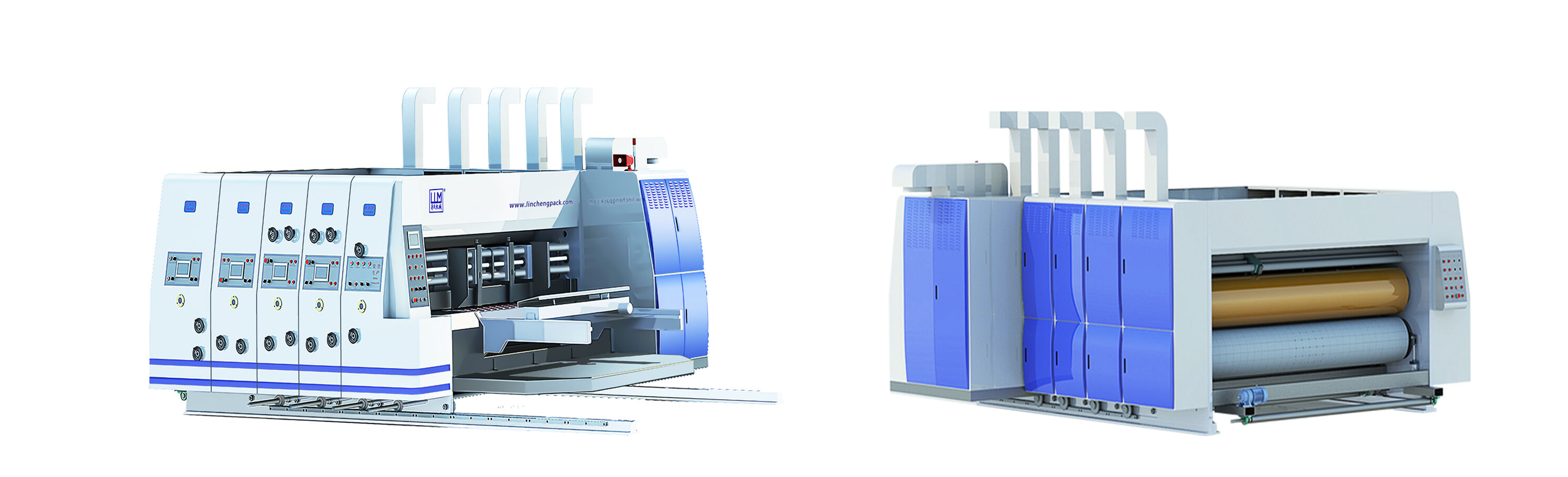

a. Full-Automatic Machine (Fast):

● Best For: If you need to make more than 30,000 boxes a day.

● Why: It is very fast and precise. It costs more to buy, but it saves a lot of money on labor (workers) in the long run.

b. Semi-Automatic Machine (Economic):

● Best For: If you make fewer than 30,000 boxes a day.

● Why: It is great for new or small factories. It is cheaper to buy and works well if you have many small orders with different sizes.

Common widths are 2000mm or 2400mm. Choose a width that fits the most popular box sizes in your local market. Bigger machines can make bigger boxes but take up more space.

● Auto-Setting: You just type the box size into a screen, and the machine adjusts itself. This saves a lot of time!

● Manual Setting: You have to turn handles by hand to change sizes. This is slow but much cheaper.

Don't make these common, expensive mistakes when buying:

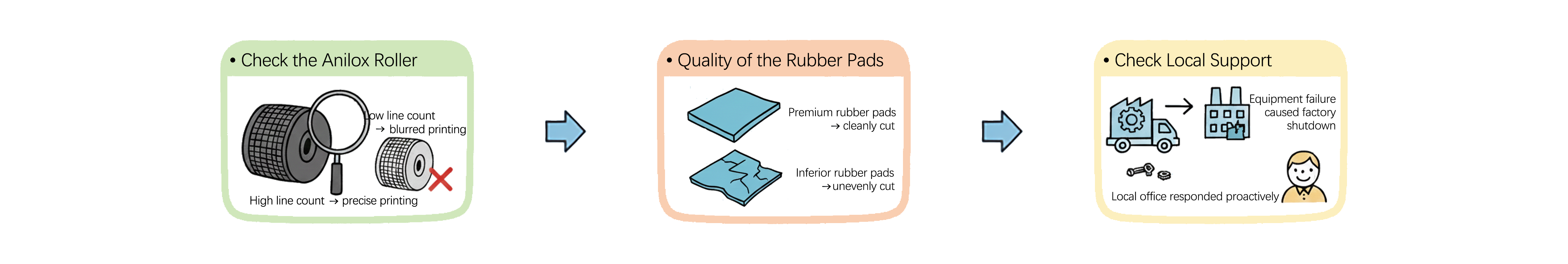

● Check the Anilox Roller: If you want to print beautiful, sharp pictures, you need a high "line count" roller. If the roller is too cheap, your printing will look blurry.

● Quality of the Rubber Pads: In the die-cutting part, the quality of the rubber pads (Anvil Covers) is very important. Cheap pads wear out fast and cause messy cuts.

● Check Local Support: If the machine breaks, your whole factory stops. Always buy from a company that has repair teams and spare parts near you.

● Clean the Ink: You must wash the ink pumps and rollers every day after work. If the ink dries inside, it will ruin the printing quality.

● Clear the Scraps: Clean up all the paper dust and scraps. If they get into the machine’s gears, they can cause big damage.

The machine uses many gears to move. Make sure the automatic oil system is working. If there isn't enough oil, the gears will wear down, and your printing colors won't line up correctly.

Whether it is printing or feeding, the rule is "be as gentle as possible." If you press too hard, you will crush the wavy layers of the cardboard. This makes the final box very weak.

In the future, machines are becoming "Inline." This means one long machine does everything: printing, cutting, gluing, and folding.

● Pro Tip: If you have enough money, look for an Inline Folder Gluer. It only needs 2 or 3 workers but can do the work of 10 people using separate machines.

Investing in a Flexo printer slotter die-cutter is a big step for any box factory. By knowing your daily goal (30,000 boxes is the magic number!) and taking good care of your machine, you can turn a simple piece of paper into a profitable product.

● Q: Why does the printing look blurry?

A: Usually, it's because the cardboard is moving too much, the printing plate is loose, or the gears are worn out.

● Q: How long does a cutting die last?

A: It depends on the paper. Usually, a good die can cut 100,000 to 300,000 boxes before it needs sharpening.

● Q: Is the ink safe for the environment?

A: Yes! Most of these machines use water-based ink, which is very safe and eco-friendly.