We expect the corrugated box market to keep growing in 2026. Two main forces drive this growth:

● Huge Boom in Online Shopping (E-commerce): As more people buy goods online, the need for shipping boxes grows fast. For example, in fast-growing markets like Vietnam, huge growth in online shopping is directly pushing up demand for boxes, showing the market will keep expanding.

● Environmental Demand: Corrugated boxes are recyclable and better for the environment than plastic packaging. This makes them popular with big brands and governments.

The market looks good overall. The key to success is controlling costs accurately and choosing the right machines.

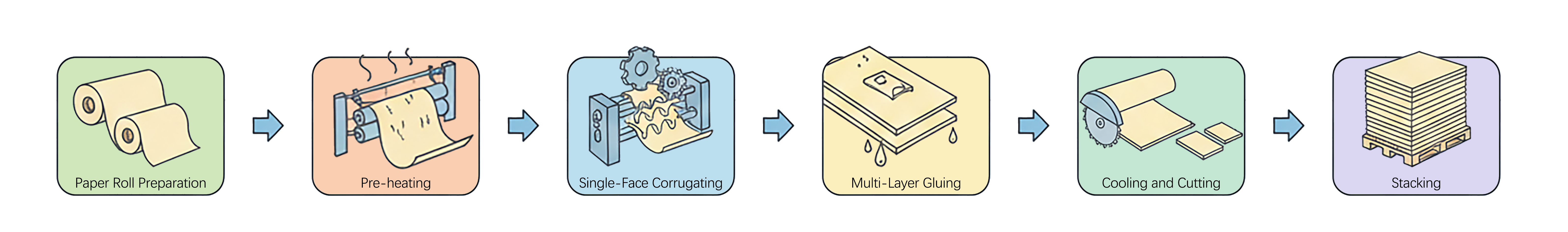

The production of corrugated cardboard is a continuous, high-temperature, high-efficiency process,here are the main steps on a corrugated production line:

a. Paper Roll Preparation: Load different types of paper rolls (liner, medium) onto the machine stands.

b. Pre-heating : Paper is heated before it enters the machine. This makes it easier to shape and helps the glue stick better.

c. Single-Face Corrugating: The center paper (medium) goes through the single-facer machine. It presses the wave-like shape (flute) into the paper using heat and pressure. Glue is added, and it is stuck to the inner liner to make a 2-layer single-face board.

d. Multi-Layer Gluing: The 2-layer board moves to the double-facer machine. Glue is added to the waves. It then sticks to the outer liner and other layers using heat and heavy pressure, creating 3-layer, 5-layer, or 7-layer boards.

e. Cooling and Cutting: The finished board cools down. It is then cut lengthwise and crosswise into the correct standard sizes.

f. Stacking: The cut boards are stacked neatly, ready for printing and final shaping.

The cost to make one corrugated board mostly comes from three areas: raw paper, glue, and energy. Attention: These costs and the final price are very different in different countries.

Production costs are not the same everywhere. They are affected by where you produce:

● Raw Paper Price: In some Asian countries with many paper mills, paper might be cheaper than in developed countries. If a country imports most of its paper, the cost will be higher.

● Labor and Management Costs: Labor costs in developing countries (like in Southeast Asia or Latin America) are much lower than in high-income countries (like Western Europe or North America). This is a huge cost difference.

● Energy Costs: Regions that rely on expensive natural gas for steam (like Europe) have high energy costs. Regions with cheaper coal power or government help have lower energy costs.

Even though the total dollar amount is different, the percentage of each cost is usually the same globally.

| Cost Item | Estimated | 2026 Price Prediction | Action Plan |

| Paper Rolls (Liner & Medium) | 70% - 85% | Prices will change a lot. They will likely increase over time because demand is growing. | Lock in long-term contracts with big paper mills for stable supply. |

| Glue (Starch) | 2% - 5% | Mostly stable, but affected by crop prices. | Improve glue mix to reduce waste. |

| Electricity and Gas (Energy) | 5% - 10% | Global energy prices are still uncertain and may increase. | Choose energy-saving corrugated production machines. |

| Labor and Management | 5% - 10% | Stable or slight increase. | Increase automation to rely less on manual labor. |

● Paper Prices: Because of global economic recovery and online shopping, paper prices should stay high in 2026. Prices may drop briefly if new paper mills open, but the pressure is mostly to go up.

● Energy Costs: Corrugators need a lot of heat (steam) to dry the boards. As global energy remains tight, gas and electricity prices will likely continue to rise slowly.

Calculating profit is complex. It depends on the board type (3-layer, 5-layer, etc.) and the quality of paper you use. More importantly, profit is very different by region.

In certain low-cost, high-demand emerging markets (like some Southeast Asian countries), low labor costs and high demand can push the Net Profit Margin to 15% or higher.

On the other hand, in high-cost, highly competitive markets (like Western Europe or Japan), production costs are high, and selling prices are kept low by competition. Net Profit Margin might only be 8% to 12%.

For large, established factories, the average Net Profit Margin (EBITDA %) is generally between 10% and 15%.

Simple Profit Example (using the global average for a basic 3-layer board):

Let's say the full cost of making one square meter of standard 3-layer board is $3.00. If the selling price is $3.45:

● Profit Per Square Meter: $3.45 - $3.00 = $0.45

● Profit Margin: $0.45 / $3.45 ≈ 13%

2026 Profit Key: To keep this 13% profit margin, you must use automation and energy-saving technology to offset the rising costs of paper and energy.

Buying a corrugated production line is the single biggest expense for a new factory , we've prepared some guidelines (→Corrugated Board Production Line Beginner's Guide)before it,we hope it will help you learn more about the process and avoid common pitfalls.

Usually,machine prices are affected by two factors:

Corrugators and stackers are mainly made of steel.

● Steel Trend: Global forecasts suggest a moderate rebound and growth in steel demand in 2026. This means the cost of making the equipment will likely go up, pushing new machine prices higher.

● Advice: If you decide to invest, the sooner you sign the purchase contract, the better you can lock in today's price.

In the corrugator industry, brand name greatly affects the price.

| Brand Type | Features | Price / Premium | Best For |

| Top Global Brands (e.g., BHS, Fosber) | Very fast (over 300 meters/min), highly automated, low breakdown rate, very energy efficient. | Highest price, significant brand premium. | Large corporations aiming for the highest speed and quality. |

| Top Domestic Brands | Good value, medium speed (180-250 meters/min), easy service, meets most needs. | Medium price, fair premium. | Medium-sized and growing corrugated box factories. |

| Economy Brands | Slower speed (100-150 meters/min), lowest upfront cost, but fewer automation features. | Lowest price, almost no brand premium. | Start-up companies with low funds or those making only simple boards. |

When choosing equipment, don't just look at the price. Top brands often bring higher efficiency and lower breakdown rates, which saves you more money and time in the long run.

For more information, please refer to our article on 2026 corrugated production line pricing, where we provide detailed explanations regarding pricing.

For an investor planning a new corrugated factory in 2026, we offer two main investment plans based on your money and market goals:

This is the standard plan for companies with stable finances and a solid market. The goal is fast growth and large-scale production.

a. Line Type: Choose a "1.8m or 2.0m width, 180-220 meters/minute speed" medium-to-high speed production line. This is the sweet spot for balancing speed and starting cost.

b. Key Equipment Choices:

● Single Facer: Choose a model with "Quick Roll Change" technology. It costs a bit more, but it lets you change the flute type (like B-flute to C-flute) in 10-20 minutes, making production much more flexible.

● Boiler System: Make sure you use a high-quality, high-efficiency steam boiler. Energy is a long-term cost, and an efficient boiler will save a lot of money on gas or electricity.

This plan is for companies with limited money or those focusing on niche markets (like small online orders or special board types).

a. Focus: Buy a complete Single Facer Line that only produces 2-layer corrugated board(in rolls).

b. Main Advantages:

● Very Low Starting Cost: You can save over 50% compared to buying a full automatic line.

● Small Space Needed: The machine is shorter and needs less factory space.

● Clear Upgrade Path: You can easily upgrade later by adding a laminating machine. This lets you glue an outer liner to your 2-layer rolls to make 3-layer corrugated board without buying an expensive double-facer right away.

c. Challenges:

● Limited Product: You cannot make 3-layer or 5-layer boards directly at first.

● Market Limit: You mainly serve the market for paper rolls or simple packaging.

Choosing the right equipment and reacting quickly to raw material prices in 2026 is the key to success for any new factory.

To succeed in the corrugated market in 2026, your strategy must focus on these three core points:

a. Opportunities and Risks:

● Opportunity: E-commerce and environmental demand will continue to drive growth.

● Risk: Raw paper prices will change a lot, and energy costs will likely rise over time.

b. Cost Control Sets the Profit Limit:

● Main Factor: Paper cost makes up 70% to 85% of the total cost. You must have good supply chain management and energy-saving technology.

● Regional Differences: Profit margins are very different by region. Emerging markets (low cost / high demand) can have much higher profit than old, competitive markets. Investors must correctly calculate costs for their specific location.

c. Equipment Must Match Your Goal:

● For Large-Scale Production: Choose a medium-to-high speed (180-220 m/min) automatic line, focusing on quick flute change technology for maximum efficiency.

● For Flexibility and Low Cost: Choose the low-investment Single Facer Line. This allows for quick start-up and easy product upgrade (by adding a laminating machine) later on.

Success finally comes down to combining advanced automation with detailed cost control, and choosing the best investment plan for your specific market area.