In today’s fast-growing packaging industry, corrugated sheets are everywhere. You’ll see them in our daliy life. The strong demand has driven the fast growth of corrugated box manufacturers. For box factory beginners, understanding the corrugated cardboard production line is necessary. It’s the first step to creating an efficient and profitable factory.

This guide explains why corrugated packaging is popular, what a corrugated board production line is, how it is set up, and how it operates.

You'll also learn why investing in it can lead to long-term success for your business in 2025.

Why are corrugated board production lines popular in 2025 and beyond?

In 2025, online shopping is growing fast. This has led to a big rise in the need for product transportation and packaging. Many materials are used for shipping packaging, like plastic, wooden boxes, and cardboard.

However, corrugated cardboard is the most popular. It’s the top choice for packaging and transporting almost all types of products. It offers many benefits. These include low cost, high strength, lightweight, flexibility, eco-friendliness, and recyclability.

Our need for corrugated cardboard is growing every day. This makes the production line that makes it more popular. In the packaging industry, few machine is as important as it.

What is a corrugated sheet production line?

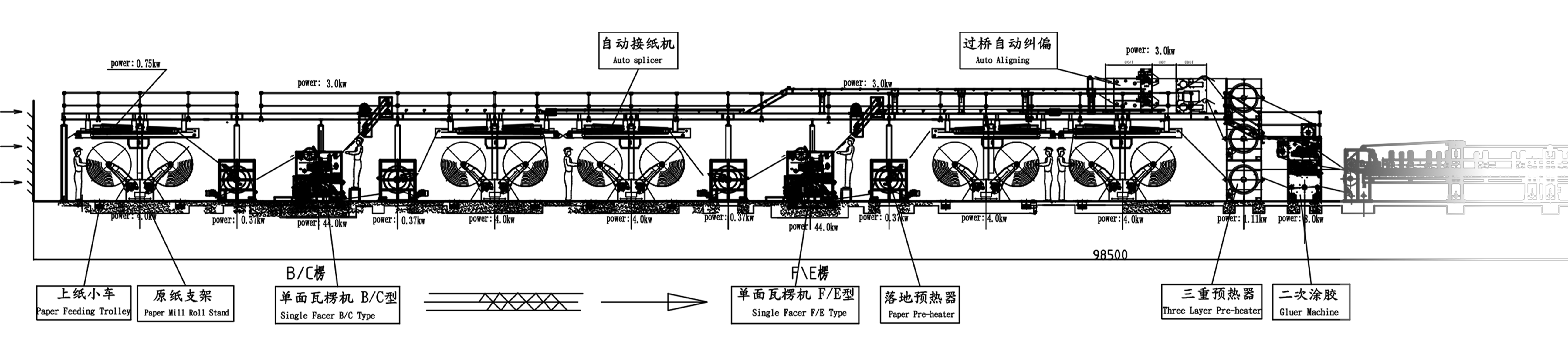

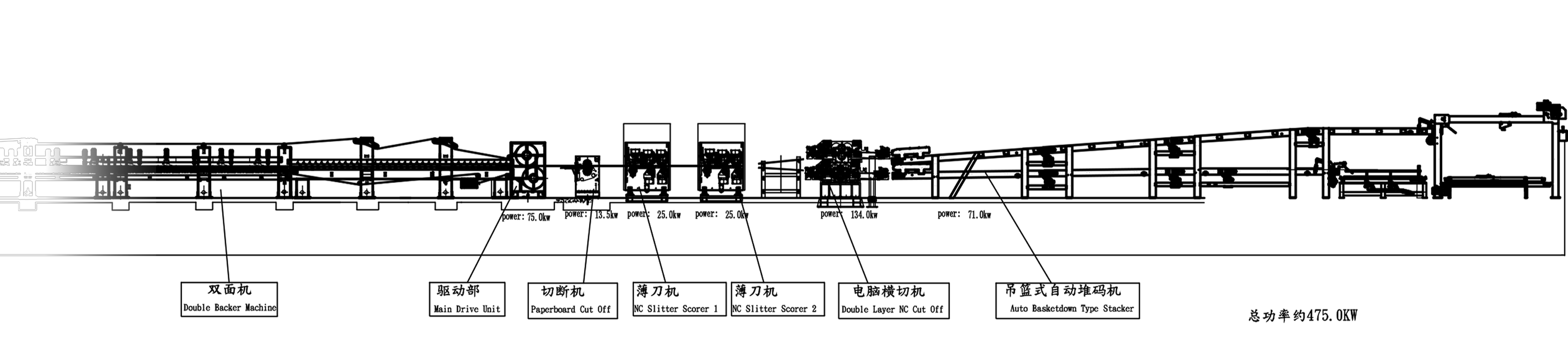

The corrugated sheet production line is a group of machines. It includes all the machines needed to make corrugated cardboard.

It combines liner paper and fluting paper into single-wall, double-wall, or triple-wall sheets.

All in all, this production line turns big rolls of paper into quality corrugated sheets. Then, these sheets can be cut, printed, and folded into packaging boxes.

How is the production line configured in an experienced corrugated cardboard plant?

A corrugated production line usually has the following parts:

Mill Roll Stand, Preheater, Single Facer, Paper Bridge, Glue Machine, Double Facer, Dryer, Slitter Scorer, Cut-off Machine, and Stacker. Each section plays a key role.

Mill Roll Stand: There are electric and hydraulic types. It holds and feeds paper rolls into the line.

Preheater: Heating the paper beforehand ensures the temperature is uniform, significantly helps the entire production process .

Single Facer: It corrugates medium paper to create the fluted layer. This layer is the main part of the production line.

Paper Bridge: The "buffer zone" on the production line balances out speed differences. This keeps operations running smoothly.

Glue Machine: Puts glue to bond the liner and flute layers together. Controlling the amount of glue is the key to saving money.

Double Facer: Adds additional liner paper to strengthen the board.

Dryer: The "fixed shaper" on the double-sided machine. It makes weak semi-finished products into strong, long-lasting final goods.

Slitter scorer: Cuts and makes creases in the board to the required size.

Cut-off Machine: Cuts the boards to the exact length needed.

Stacker: Collects and piles up finished corrugated sheets.

Even though production lines use similar basic equipment, each machine has different models. These different models lead to differences in how fast and efficiently they produce,take lum as an example:

| Model | Design Speed (m/min) | Economic Speed (m/min) | Working Width (mm) | Flute Selection | Multi-ply Board |

| LUM-A | 120 | 80-100 | 1400-2200 | A,B,C,E,F TYPE | 3/5/7 Ply Board |

| LUM-B | 150 | 100-120 | 1400-2200 | ||

| LUM-C | 200 | 150-180 | 1400-2200 | ||

| LUM-D | 250 | 200-220 | 1800-2800 | ||

| LUM-S | 300 | 250-280 | 1800-2800 |

Experienced carton manufacturers always adjust their production lines. This is according to how big their factory is and how many orders they get. The best solution is the most suitable one. A suitable production line can help make more money while cutting costs. Otherwise, it will lead to wasted resources and increased expenses.For example:

| Comparison of A&B Factory Corrugated Production Lines |

||||||

| Daily Demand | Speed | Worker | Time Required To Meet Demand/day | The Price Of Machine | The Price Of Cardboard | |

| Factory A | 50000 m | 300 m/min | 8-10 | 3h | 190w $ | 1000$/t |

| Factory B | 50000 m | 100 m/min | 8-10 | 8h | 35w $ | 1000$/t |

It’s clear that Factory A will make more profits,factory B spend more on machines than factory B. A well-designed production line configuration will meet our needs and cut costs overall.

By 2025, many factories will switch to fully automatic production lines. However, this choice will depend on how much labor costs and how much they need to produce. We need to think long-term to plan better. Then we can meet current needs and keep room for growth in the next ten years.

Working Principles and Characteristics of Corrugated Board Production Lines

The corrugated production line works with heat, pressure, and keeping everything in sync.

The fluting paper passes through heated rollers to form the wavy flute structure.

Glue is applied to the tops of the wavy paper.

Liner paper is pressed onto the flute layer, forming a single-faced board.

Extra liner paper is added for double or triple-wall boards, depending on the requirements.

Key Characteristics:

High Efficiency: Continuous automatic work ensures stable, large-scale output.

Stable Quality: Computers' control of temperature, speed, and glue guarantees that the product is always the same.

Flexibility: Adjustable settings allow for different types of boards and thicknesses.

Energy Saving: Modern systems use smart heat control and steam that can be reused.

The Benefits of Establishing a Corrugated Cardboard Production Line for Packaging Factories

First, we need to know corrugated cardboard is essential for packaging and translation.

More online shopping → Greater demand for corrugated cardboard → More stable profits for corrugated box manufacturers

Box factories with their own corrugation lines do better than those relying on outside suppliers.

Cost reduction: In-house corrugated board production eliminates the need to depend on suppliers.

Faster delivery: Direct control over production schedules enables the meeting of urgent deadlines.

Enhanced quality control: Customized strength, thickness, and dimensions per order specifications.

Expanded profit margins: Get more opportunities from global e-commerce, food, and delivery industries.

Sustainability: The use of recycled materials and energy-efficient systems keeps production eco-friendly.

the growth of online shopping get The steady need for corrugated boxes. In the future, technology will drive factories forward. This will start a new era of smart corrugated manufacturing.

Conclusion

The corrugated cardboard production line is the heart of every packaging factory.

More information about it helps new manufacturers make smart, long-term investment decisions.

You can consult LUM–HEBEILINCHENG for free. This applies whether you’re planning a new factory or upgrading equipment. We’ll look at your factory’s conditions and create a production line for you. It will fit your budget and goals. This way, you can take advantage of new chances in the global packaging market.

This concludes this guide. We hope you find it helpful.

Author: LUM

Our founder, Lu Dong, has been involved in the corrugated machinery industry since 1999. He established Jidong Light Industry in 2007 and founded Hebei Lincheng Packaging Machinery Manufacturing Co., Ltd. in 2014.

To this day, he remains deeply committed to the corrugated machinery industry, staying true to his original aspirations.

Our company design philosophy has been “Stable For More.” We focus on making reliable and durable machinery.

To better serve our international clients, we are focusing on two key areas. On one hand, we constantly update our equipment with the latest technology. This makes it more efficient and less likely to break down. We've opened offices in Egypt, Uzbekistan, Turkey, and Russia. More locations are coming soon. We’re also building strong connections with local agents. This ensures fast after-sales service.

These efforts help packaging plants improve their processes. They also cut costs and build a strong competitive edge.

Wherever you are, LUM is always by your side.No matter when, lum keeps moving forward.

Table of Contents

- Why are corrugated board production lines popular in 2025 and beyond?

- What is a corrugated sheet production line?

- How is the production line configured in an experienced corrugated cardboard plant?

- Working Principles and Characteristics of Corrugated Board Production Lines

- The Benefits of Establishing a Corrugated Cardboard Production Line for Packaging Factories

- Conclusion

- Author: LUM