The Secret of Cardboard "Layers"

Cardboard (corrugated board) is everywhere—it’s the basic material for most shipping boxes. The layer count (3, 5, or 7) simply tells you how tough the box is.

Perhaps many people may ask: Is 7-ply better than 5-ply? The answer is yes.

To a certain extent, 7-ply corrugated cardboard offers superior quality compared to 3-ply and 5-ply varieties, More layers mean stronger protection for the things inside. But it also comes at a significantly higher price.We need to understand it and choose it.

If you are a business planning to buy a cardboard production line, you need to know the big differences in machines, cost, and what each line is best used for. Choosing the right one helps you work smarter and make more profit!

Box Structure and Toughness: Seeing the Differences Easily

Think of corrugated cardboard as a paper "sandwich." It is made up of flat outer papers (called linerboard) and a wavy paper layer (called fluting) glued together. A different layer count means you have different numbers of flat and wavy pieces in your sandwich.

Corrugated carton box manufactors will product 3-ply, 5-ply, and 7-ply corrugated cardboard usually.

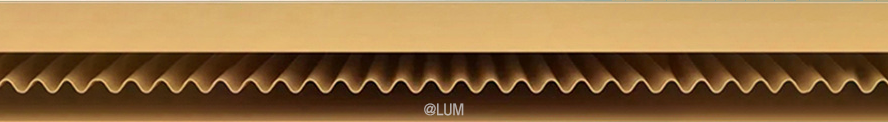

3-Layer Board (Single Wall): The Light and Simple Choice

-

Structure: 1 Outer Paper + 1 Wavy Paper + 1 Inner Paper.

-

Characteristics: This is the lightest and thinnest board. It gives basic soft padding but is not very good at resisting heavy crushing.

-

Application: Good for packing small, light items, like food boxes, shoe boxes, or just for padding inside a bigger box.

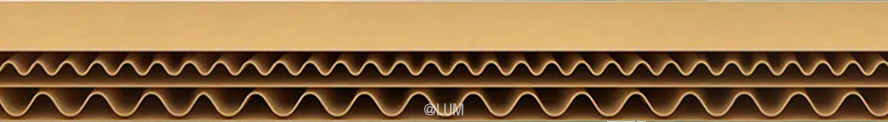

5-Layer Board (Double Wall): The Standard and Strong Choice

-

Structure: It’s basically two 3-layer boards stuck together: 2 Wavy Papers and 3 Flat Papers in total.

-

Characteristics: Much stronger and harder to crush. It can carry a good amount of weight. This is the most common type of box on the market.

-

Application: Used widely for things like home appliances, TVs, heavy electronics, or most regular shipping needs. For most companies, the 5-layer cardboard machine is the standard, best choice.

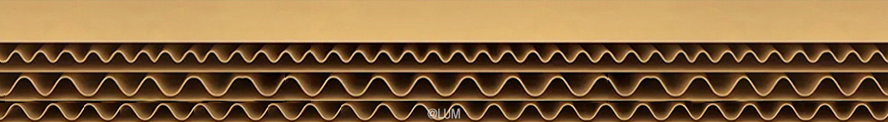

7-Layer Board (Triple Wall): The Super Heavy-Duty Defender

-

Structure: This is made up of three wavy paper layers and four flat paper layers. It is the thickest and toughest board.

-

Characteristics: Extremely hard to crush and very resistant to being pierced or punched through. People sometimes call it "super-tough cardboard."

-

Application: Used only for very heavy items like large machinery, delicate high-tech equipment, or for export shipping where the box needs to replace a wooden crate. Buying a 7-layer cardboard machine is for businesses with these special, heavy-duty needs.

Machine Setup: The Number of "Wave Makers" is the Key

The biggest difference in the machines needed for different board layers is how many "Single Facers" (let’s call them Wave-Making Machines) you need. The Wave-Making Machine is the part that turns flat paper into the wavy part and glues it to the first flat paper.

Main Difference: How Many Wave-Making Machines?

| Layers | Line Type | Required Wave-Making Machines | Common Wave Sizes (Flute Types) |

| 3-Layer | Single Wall | 1 Machine | C or B Wave Size |

| 5-Layer | Double Wall | 2 Machines | BC or AC Wave Sizes (Usually two different sizes) |

| 7-Layer | Triple Wall | 3 Machines | BCA or CCA Wave Sizes (Three different sizes) |

The heart of the single-face machine: the corrugating roll

Embossing rollers are one of the most important components in a single-face corrugator. They press the paper into flute shapes like A, B, C, E, F, T, W, and V. These shapes decide how strong and how thick the corrugated board will be. Among them, A, B, and C flutes are the most common.

What Changes for Gluing and Drying?

What Changes for Gluing and Drying?

As the board gets thicker with more layers, other parts of the machine also need to be stronger:

-

Gluing System: The 7-layer cardboard machine needs a very precise and powerful gluing system to make sure all seven layers stick together perfectly.

-

Drying Section: Thicker boards (like 5-layer and 7-layer) need a longer hot plate area. This is because the glue has more water, so it takes longer to heat and dry completely. This stops the board from bending or warping.

-

Smart Controls: Modern, fast production lines often use advanced computer control systems, like the Beckhoff system. This smart control helps the machine make quick changes between different box orders and keeps the whole process running smoothly.

Cost: Investment and Running Expenses Compared

More layers mean the machine is more complicated, which directly affects the initial cardboard machine price and the daily running costs later on.

Starting Cost: More Layers, Higher Price

-

3-Layer Line: Lowest cost to buy, as it only needs one core machine setup.

-

5-Layer Line: Medium cost, usually about 1.5 to 2 times the price of a 3-layer line.

-

7-Layer Line: Highest cost to buy. Since it needs more Wave-Making Machines, more gluing parts, and a longer drying area, the machine is much bigger and more expensive.

Daily Running Costs: Steam and Glue Used

-

Paper Use: A 5-layer board uses 2 more sheets of paper than a 3-layer board, and a 7-layer board uses 2 more than a 5-layer board.

-

Energy Use (Steam/Heat): Making thicker boards (5-layer and 7-layer) uses more steam to heat the longer drying section. This means higher energy bills.

-

Workers and Repairs: The complex 7-layer cardboard machine needs highly skilled workers to run and fix it, so the repair and labor costs are also higher.

The price of a 3-layer to 7-layer corrugated board production line can range from tens of thousands to several million dollars. For many new box factories, this is a very large investment. The high start-up cost is also a main reason why many factories fail to open.

There is actually a more affordable option. You can use a single-facer line. It can produce simple 2-layer board. If you add a laminating machine, you can make 3-layer corrugated board. This helps reduce your start-up cost by a lot.

Conclusion: How to Choose the Best Machine for You

Choosing which cardboard machine to buy is not just about your budget; it should be based on what your customers need the box for:

-

If you pack light things: Buy a 3-layer machine for the cheapest and fastest production.

-

If you serve the general market (Most Common): Buy a 5-layer machine. This is the most flexible choice that fits most customer orders and offers good returns on your money.

-

If you specialize in super heavy items: Buy a 7-layer machine. Though the starting price is high, it gives you a special advantage in the tough, high-strength packaging market.

Before deciding, make sure to talk to expert machine makers to get a personalized cardboard machine quote. They can match the best machine to your factory size, budget, and how many boxes you need to make.

Author: LUM

Our founder, Lu Dong, has been involved in the corrugated machinery industry since 1999. He established Jidong Light Industry in 2007 and founded Hebei Lincheng Packaging Machinery Manufacturing Co., Ltd. in 2014.

To this day, he remains deeply committed to the corrugated machinery industry, staying true to his original aspirations.

Our company design philosophy has been “Stable For More.” We focus on making reliable and durable machinery.

To better serve our international clients, we are focusing on two key areas. On one hand, we constantly update our equipment with the latest technology. This makes it more efficient and less likely to break down. We've opened offices in Egypt, Uzbekistan, Turkey, and Russia. More locations are coming soon. We’re also building strong connections with local agents. This ensures fast after-sales service.

These efforts help packaging plants improve their processes. They also cut costs and build a strong competitive edge.

Wherever you are, LUM is always by your side.No matter when, lum keeps moving forward.