Main structure:

1.The machine-wide computer control, easy to operate, simple; store 1000 single nail;

2.Bottomless box with a lap can be nailed (its required when place order);

3.3-5 minutes to adjust the size, simple and quick;

4.Nail-head power servo motor, mechanical speed: 800 nails / min;

5.Feed the leading edge of the Department of vacuum adsorption belt feeder to ensure that cardboard boxes are not skewed; Feed the leading edge of the machine can be individually adjusted belt level to increase the service life;

6.When feed side lapping device can send paper neatly smooth;

7.Feed unit adopt PLC control system to ensure that the nail from the stable and accurate,conveyor belt can adjust easily to prolong machine life.

8.Paper feed motor use servo motor control to ensure stable and accurate nails from;

9.This machine is designed with plastic function, make sure it won't appear in the nailing scissors, neatly not skew;scissors mouth does not exceed plus or minus 1mm around the machine to ensure that;

10.The machine can be nailed single screw, twin screw, strengthening one-time completion;

11.Matched with computer screen operation and displays the machine fault description;

12.The machine can be nailed three layer, five layer carton (noted in advance with order when its required for a seven layers board);

13.The machine finally has automatic counting,stacking,order output.

14.The native baling part is for matching when order.

15.The machine has three function combination, can stick, nails, nail stick at the same time.

Main part instruction:

1.Feeding parts:

Paper adopts frequency control of motor adjust speed, the vacuum adsorption belt front, equipped with side beat device, ensure that your paper is not skewed.

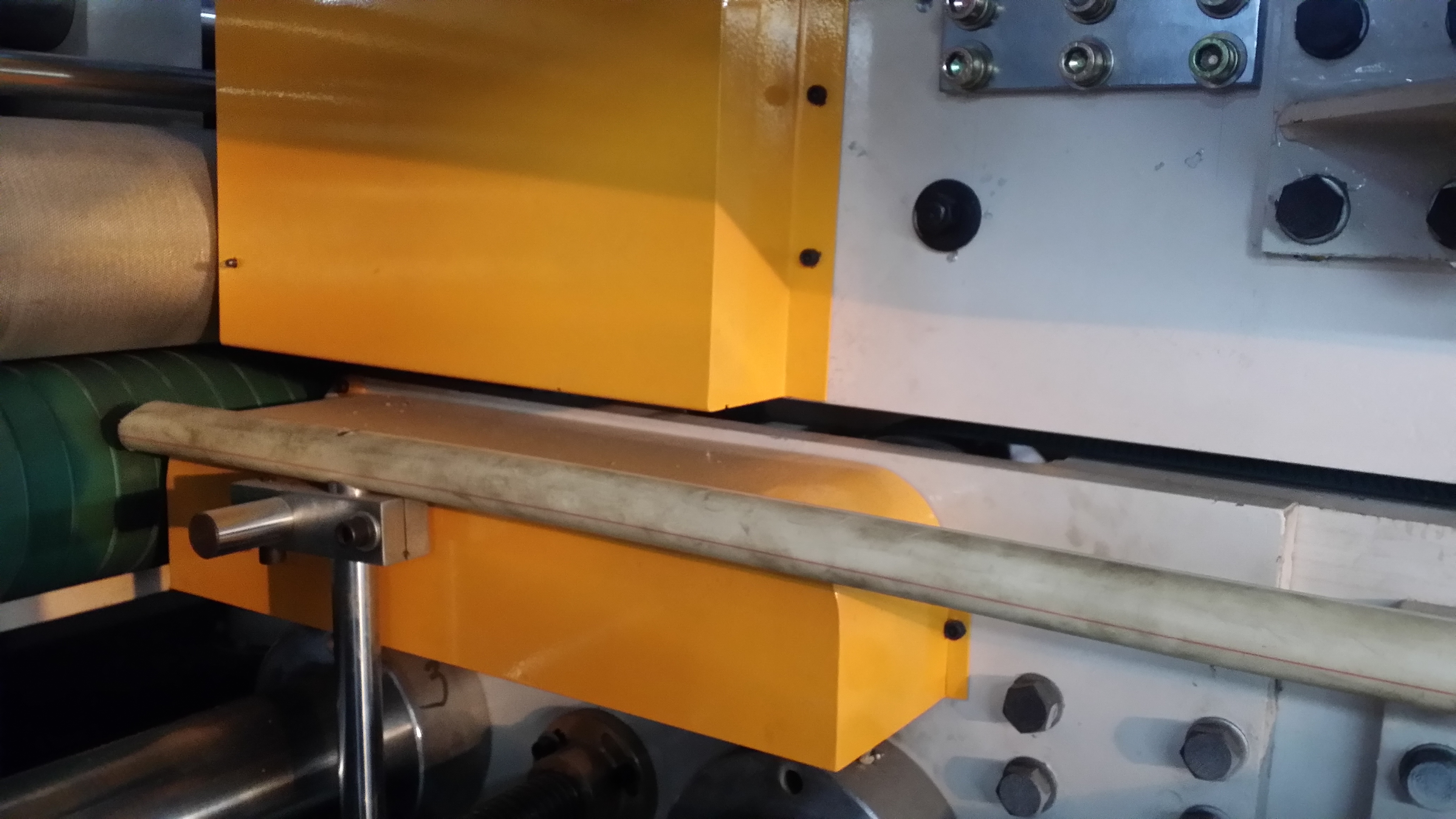

2.Folding parts:

The biggest characteristic of folding part is equipped with scoring wheel,second scoring, the original scoring rolling back again.This makes after folding carton is more beautiful.The machine after folding department before nailing there will be a plastic device, before nailing will again plastic folding carton, ensure the nail out of carton no scissors.

3.Correction parts:

Correction unit servo motor correction, correction and then pressed into the nail me with a belt section out of the box to ensure that no permit scissors mouth;

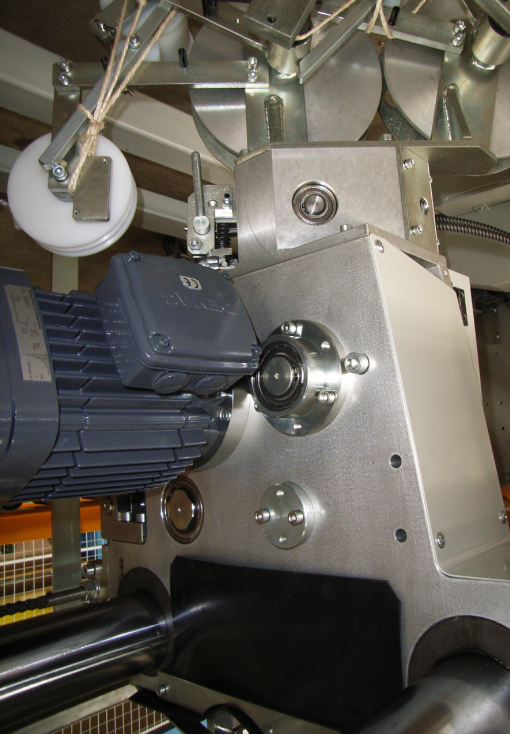

4.Stitching parts:

Stitching head adopt nailing head,Italian imported, using special materials, wear and difficult to damage,nail speed is 800-1200 nails/minute, the largest feature of this machine is the swing of the head directly driven by servo motor speed, stable and accurate. It can be achieved to stitch a single nail, double nails, strengthen nails, head and tail nails (middle stick) operation for the carton . Nail wire with a 2-plate 30 kg automatic to feeding wire automatically, reducing change wire time,improve efficiency.

5.Counting stacking parts:

According to the number set on the computer, automatic counting, automatic correction, is sent out automatically.

6.Automatic strapping parts:

From counting of stacking cartons into a file to automatic baling front-end, rotate 90 degrees, and then about code, into the baling machine for baling.Baling machine can choose to play "ten" word, also can choose to play the words "two".

Main introduction of each unit

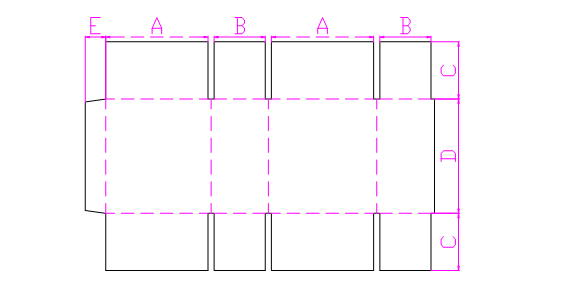

A: Machine configurations:

| Max.size(A+B)X2 | 2600mm | Min.length A | 180 mm |

| Min.size(A+B)X2 | 720mm | Max.height D | 1150 mm |

| Max.size(C+D+C) | 1200mm | Min. Height D | 250 mm |

| Min.size(C+D+C) | 300mm | Maximum width of the tongue E | 35-40 mm |

| Min.cover C | 25mm | Mechanical length | 17000mm |

| Max.cover C | 560 mm | Mechanical width | 4650 mm |

| Max.width B | 1320 mm | Mechanical weight(T) | 18 |

| Min.width B | 180 mm | Mechanical speed (nail/min) | 1200 |

| Max.length A | 1320 mm | Nail number | 1-99 |

B Stitching head :

| Swing stitching head speed | 800 nail/min |

| Min.cardboard thickness | 4mm |

| Max.cardboard thickness | 12mm |

| U type Nail in wide | 12mm |

| Flat wire specifications | 17#(2.0x0.75) |

| Nail box tilt | 45 |

| Nail minimum distance | 30mm |

| Motor power | 12kw |

C. Stacker part:

| Min. stacker width | 300mm |

| Max.stacker width | 1600mm |

| Max.stacker length | 250mm |

| Min.stacker length | 1700mm |

| Speed | 120m/min |

D. Strapping part:

| Min.strapping width | 350mm |

| Max.strapping width | 1200mm |

| Max. Strapping length | 1300mm |

| Min.strapping length | 300mm |

| Single strapping speed | 0.5s |

Main spare parts:

1. Servo motor, Japan Yasukawa brand;

2. Inverter, contactors are Schneider brand,Germany;

3. PLC is used by the Omron brand;

4. Touch screen for the Kunlun pass too;

5.Photoelectric switches, proximity switches, circuit breakers for the Schneider brand;

6. Stitching head,adopt Italy imported swing-type head, nail speed is faster and more accurate.

7. Cylinder, solenoid valve adopt the YadeKe brand,Taiwan; the main key cylinder solenoid valve is used by the SMC brand,Japanese;

8. All parts of the machine is making by precision CNC machining center processing;