The former are very necessary in the production of boxes. They also help make that bumpy pattern that gives cardboard its strength. We wouldn’t be able to make sturdy boxes to hold anything without corrugator rolls.

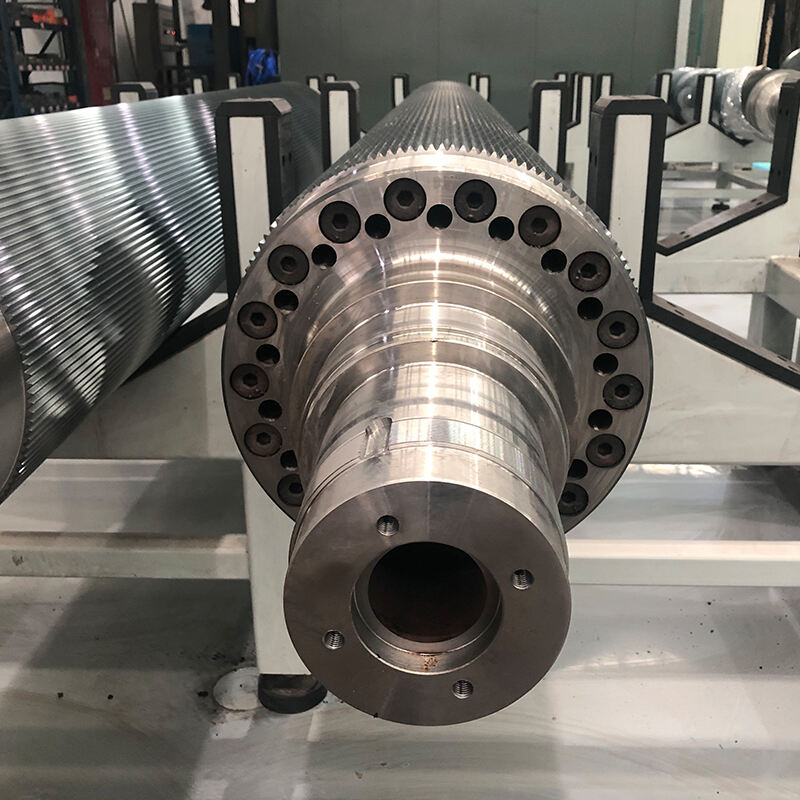

A corrugator roll is a huge metal tube with bumps on it. These bumps make the cardboard wrinkly. As the cardboard passes through the corrugator machine, the rolls squash it to form the distinctive corrugated shape. It's the combination that provides cardboard with its strength and durability.

The corrugator rolls are produced via special machines at Lincheng company. Those machines are so sensitive and you make sure the bumps in the rolls are perfect. When these rolls crush the cardboard, they form the wavy pattern we’ve become so fond of. It is this pattern that makes the cardboard so it won’t easily bend or break.

Packaging materials are made with the aid of corrugator rolls. Without them, it would be difficult to create boxes strong enough to hold heavy things. When the Lincheng company manufactures a new set of corrugator rolls, the rolls are meticulously scrutinized to be certain that they function properly. This ensures that the boxes produced using these rolls will be durable and dependable.

But like other machines, corrugator rolls must be maintained. Fact is, the Lincheng company knows this and maintains their rolls well. They clean and inspect the rolls frequently, to ensure they work properly. This serves to eliminate any issues that could cause a problem for the quality of the cardboard.

The rolls of Lincheng company are producted with the advanced technology. They have these special machines that make the rolls with amazing accuracy. This accuracy is what makes the rolls so efficient in the creation of that wavy pattern across the cardboard. With use of the most advanced technology, Lincheng can assure the quality of their corrugator rolls.