Corrugated making machines are so fun! This post will look at how they function, and why they are such an important part of making boxes and other packaging materials. Lincheng have the best corrugated manufacturing machines on the planet!

What's interesting is the technology that goes into these machines. These machines are pretty much big robots that take flat pieces of cardboard and transform them into corrugated boxes. They cut, fold and glue the cardboard using special tools and gears. It’s like magic!

Packaging has evolved quite a bit thanks to corrugated manufacturing machines. Before there were machines to make boxes, people had to do it by hand. It was time-consuming, and the boxes were not always very sturdy. But now, with these machines, you can make boxes quickly and in bulk. It makes it so much easier to package and post things.

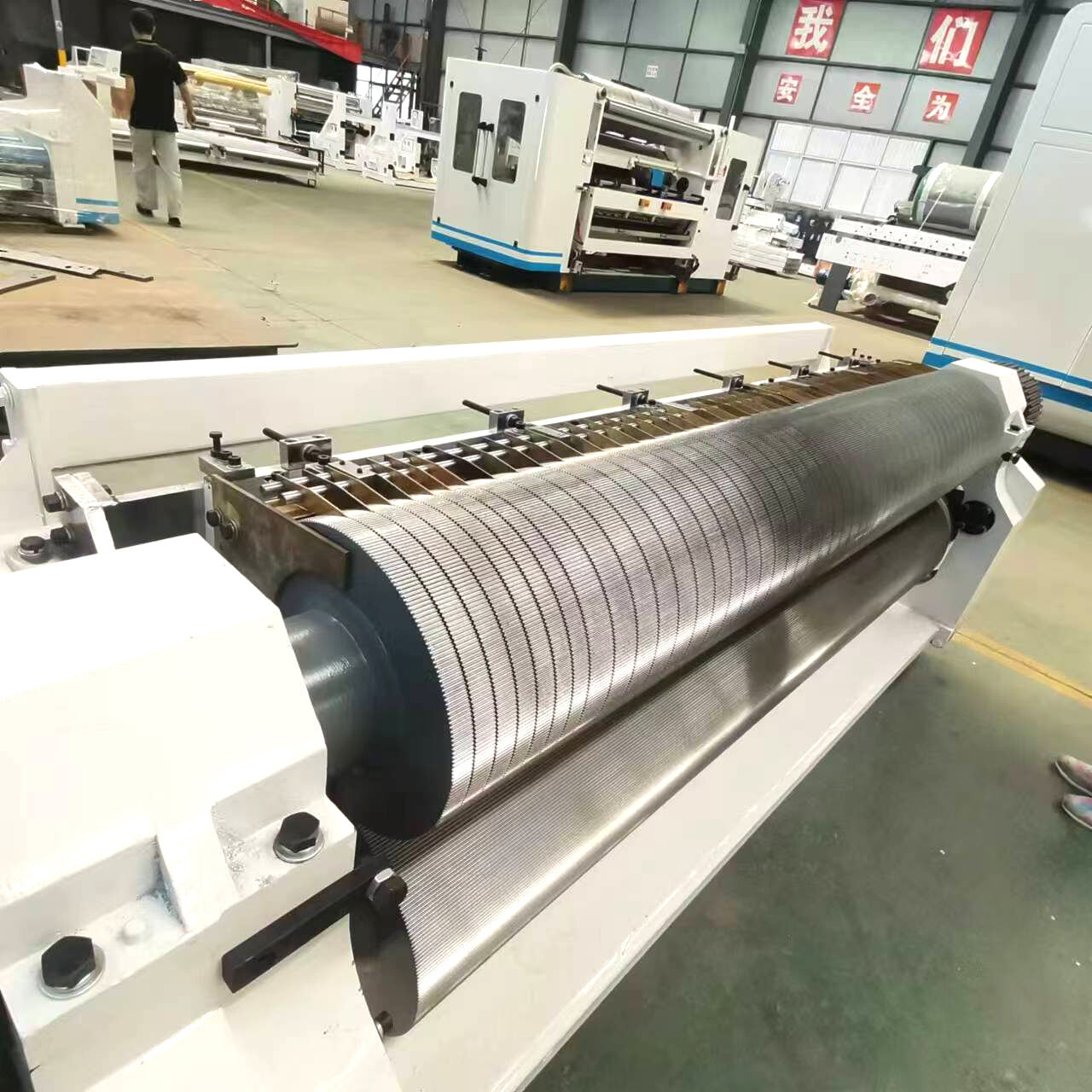

The interior of corrugate making machines is so interesting. Rollers inside move the cardboard through various stages. There are also blades to shear the cardboard into the proper shape and dimension. And there are glue guns that hold everything in place. It’s like a giant puzzle assembling to become a box!

The advantages of having these devices are great. For companies that produce numerous products that must be shipped, these machines can save significant time and money. The boxes these machines produce are also incredibly sturdy and can withstand the rigors of shipping. This translates into less broken merchandise and happier consumers.

It is really cool how corrugated boxes are made with these machines. SHEETS OF CARDBOARD FLAT Sheets of cardboard are fed into the machine first. Then, the cardboard is passed through rollers, which add the corrugated layer. Then the cardboard is trimmed and bent in box shape. The box is then glued together and shipped off to be filled with product. It is a quick way to make boxes!