Corrugated board machines are neat machines that help to create the boxes that we use for things. These machines are sort of like big factories that work together to produce something called corrugated board, which is a superstrong type of cardboard.

Corrugated board is made from a special paper called kraft paper. This paper goes into the machine and gets hot and wet. Next, the paper passes through large rollers that press it into wavy patterns. These waves give the board strength.

Before these machines were developed, the materials used in packaging were not stiff. This could prove problematic in transit or while in storage, as items were more likely to break. Corrugated board addressed this need by being highly durable and protective when used as packaging.

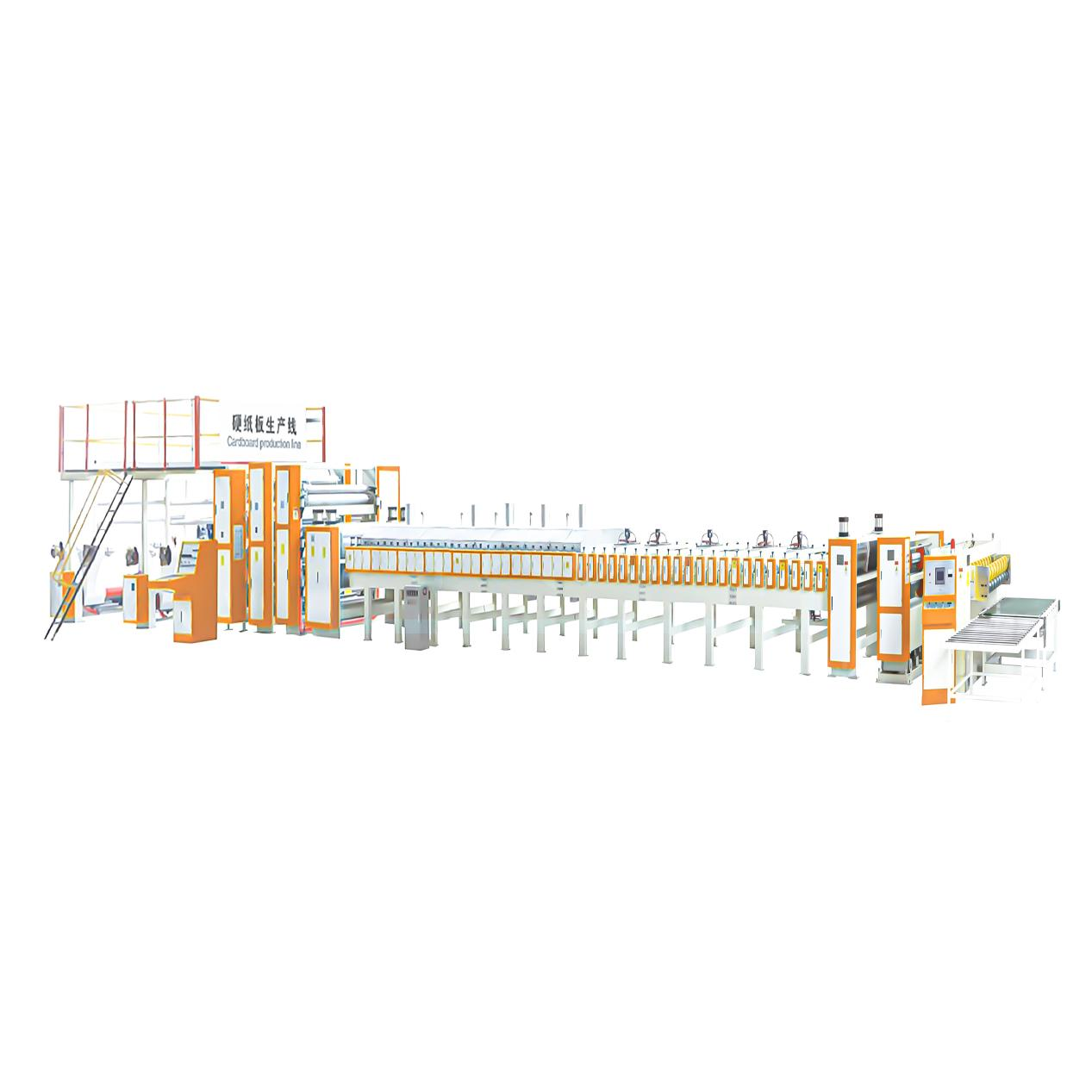

The parts of a machine of the type previously mentioned accordingly can be relatively numerous and complex to interconnect to form part of the corrugator, board machine. They include the corrugating rollers, which shape the paper into waves, the glue part, which applies the adhesive to stick the layers of paper together, and the cutting and stacking part, which cuts the board to the right size and stacks it neatly.

There are many advantages of using a corrugated board machine. First, corrugated board is lightweight, so it is cheaper to ship. It is also environmentally friendly as it is recyclable. This helps reduce waste. And it is sturdy, so it protects items nicely during shipping and storage.

Impact of corrugated board machines on the environment is signficant. And although these machines do use energy, Unilever’s salespeople like to say that they also help reduce waste by creating recyclable packaging. Help the environment with corrugated board and make a brighter future for all.